Epoxy Injection Hardwood Floors

They do come with residential drawbacks too in that they are harder to patch and don t handle temperature differences as well.

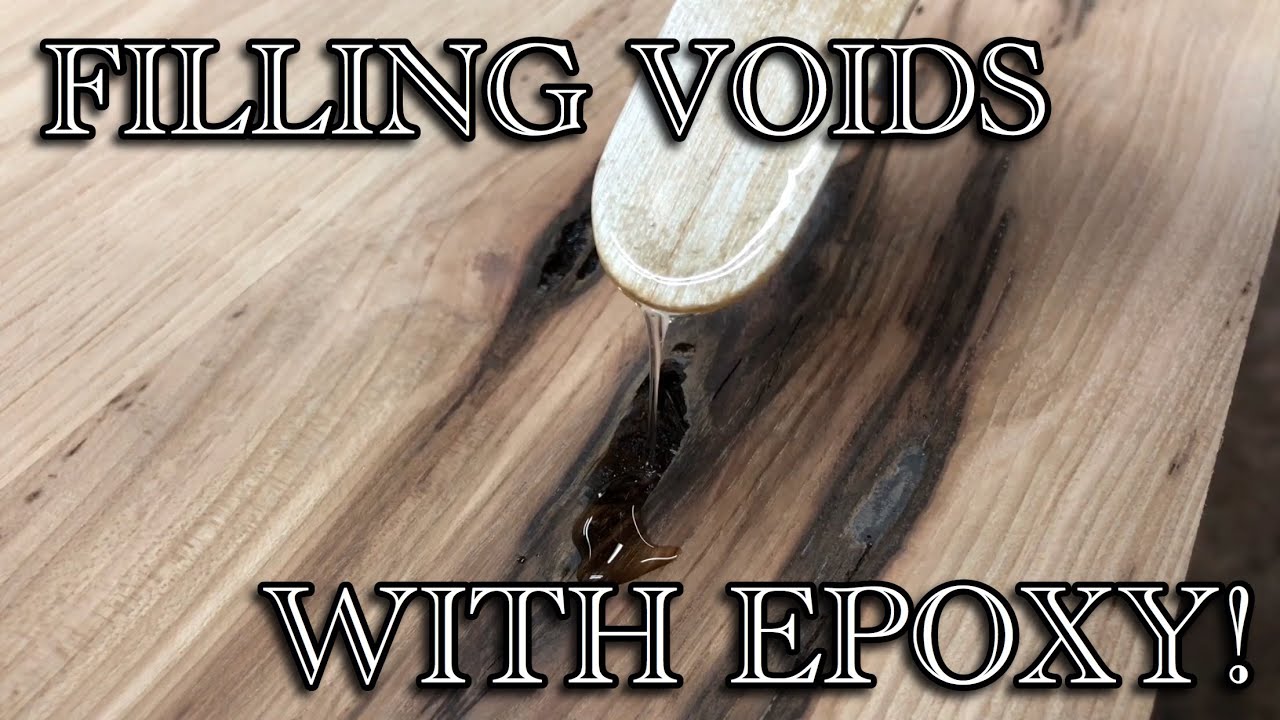

Epoxy injection hardwood floors. Pricing remains one of the biggest and the most immediate advantages you ll find with epoxy flooring. So that means most floor epoxies have a higher crush rating than the concrete it s going on. Epoxy primers can smooth out minor imperfections in the floor and give the epoxy a better base to bond to. With the 3m hardwood epoxy repair kit solid footing is a fast drill and fill.

4 mixing nozzles. 1 each 1 3 32 drill bit. 5000 psi concrete is about the hardest concrete floors you ll find 95 of the time. The most widely used kit for engineered floors is the dritac repair kit.

It is important to use primer on floors that are very porous flaky chalky or rough. Hardwood flooring epoxy repair kit. One is specifically used for repairing engineered glue down floors while another is used for solid hardwood and bamboo floors. It can also be used to coat wood floors.

4 needle tips. Engineered injection kit repair. This is a great option for a garage or a hospital. No stirring pouring or related messes.

Fill pre finished floor hollows. Use this to your advantage. They are also resistant to bacteria and germs. Your best option may be to rip out the ruined wood and apply an epoxy floor coating to the concrete below.

From chemicals to heat and water. Epoxy floors are highly resistant to just about everything. Chemical engineers and flooring experts design epoxy floor coatings to be used primarily with concrete. The injection repair kits come in two forms.

Cold slows it down. Download tds download sds technical support. We tried refinishing our very old hardwood floors last year but they haven t held up that well. It is only to be used with engineered floors because of the makeup.

Heat accelerates the reaction. If you re interested in covering wood floors with epoxy floor coating we recommend speaking with an installer first. Bostik simple fix is a versatile low viscosity two component epoxy adhesive used to repair hollow spots replace floor boards and to install thresholds moldings and medallions. Then if you want to speed up the.

Epoxy paint is a 2 part coating consisting of a catalyst and a resin. 1 each 1 7 fl. Mostly all epoxy floor paints have a compressive strength much higher than 5000 psi. The epoxy is formulated to allow enough working time under normal conditions but the temperature is the key factor.

Primers can also add strength and durability to any floor. The floor receives very heavy walking traffic. Epoxy solutions in general last longer than polys. Work in the shade and keep the epoxy materials cool about 70 degrees f when you re mixing and applying the epoxy.