Epoxy Vinyl Ester Chemical Resistance

However most are prepared solely with reactive vinly type monmomers.

Epoxy vinyl ester chemical resistance. Vinyl ester or vinylester is a resin produced by the esterification of epoxy resin with unsaturated monocarboxylic acid. Standard epoxy vinyl ester resins are limited to 220 250 of 104 121 oc in most applications. Vinylester is essentially a styrene modified epoxy resin. 1 the degree of retardance achieved in properly formulated cured products made of these resins is most frequently.

To achieve the highest bond strength and water resistance use lbi s 901 vinylester resin. Chemical 1 2 630 633. Acetone nr nr s 3 s 3. Epoxy vinyl ester resins also find uses in coatings particulalry for the marine building and construction industries due to their excellent corrosion and weathering resistance.

Derakane 8084 resin is an elastomer modified bisphenol a epoxy vinyl ester resin that offers very high toughness impact and. Vinyl esters have enhanced mechanical properties compared to polyesters with physical strength better impact and thermal shock resistance. Due to its high molecular weight and low permeability it will withstand exposure to a broad range of acids caustics and solvents. Derakane 411 series resinsare the globally recognized standard for epoxy vinyl ester resins.

Epoxy vinyl ester resin that offers very high toughness impact and fatigue resistance and excellent adhesion. It is the resin of choice for demanding structural applications and as a primer for chemically resistant frp linings. In some cases conventional solvents such as xylenes are also used. They offer excellent toughness and fatigue resistance.

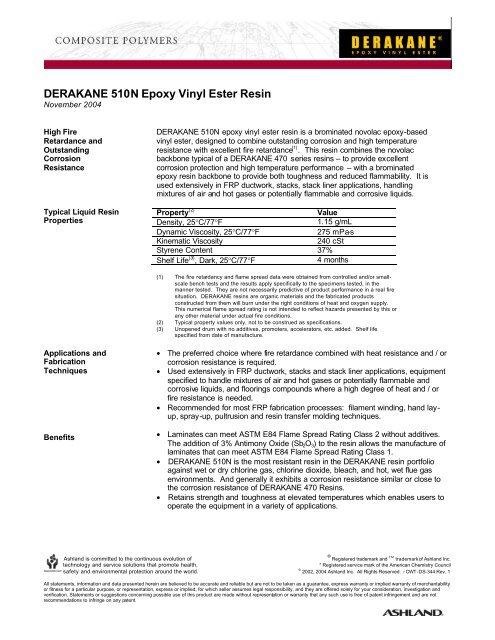

Derakane 510n resin is brominated epoxy novolac vinyl ester resin that offers a high degree of fire retardance1. It is the most resistant resin in our portfolio against chlorine bleach and hot wet flue gas environments.