Ethylene Vinyl Acetate Foam Melting Point

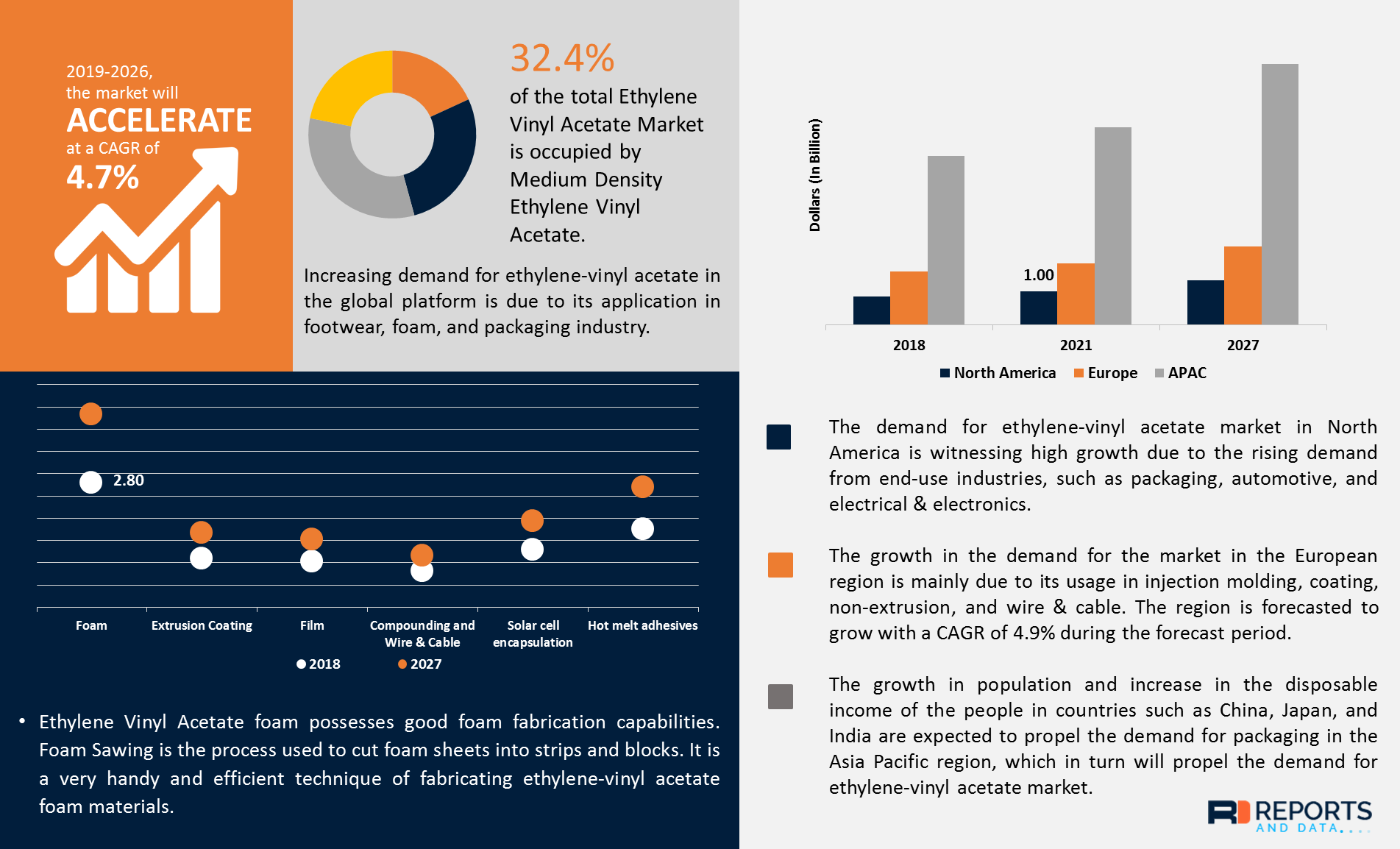

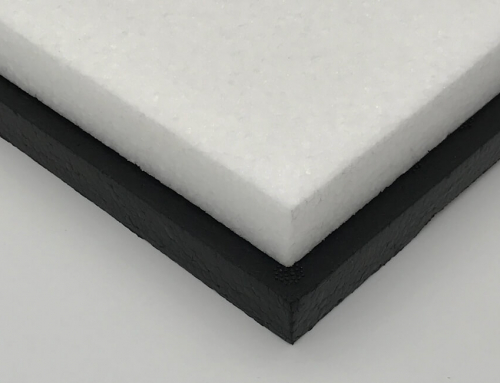

The weight percent of vinyl acetate usually varies from 10 to 40 with the remainder being ethylene.

Ethylene vinyl acetate foam melting point. Ldpe lldpe whereas a higher percentage of eva is often used to reduce the melting point and to improve the low temperature. 1 201 767 0414 fax. The va comonomer interferes with chain packing reducing crystallinity and thus lowering t m and improving transparency when compared with ldpe. Emblem in packaging technology 2012.

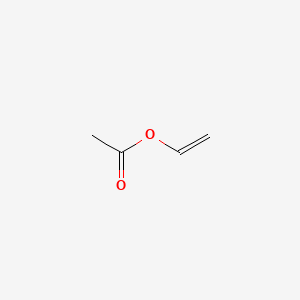

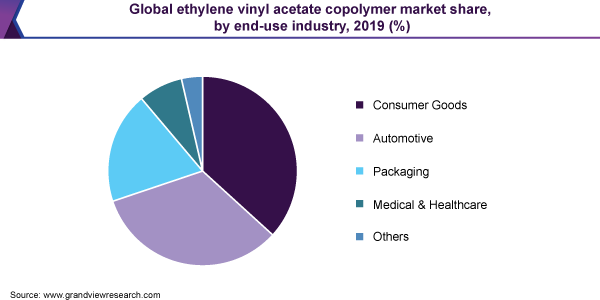

Ethylene vinyl acetate eva resins may thermally degrade and release corrosive by products. Fda status information elvax 460a resin complies with food and drug administration regulation 21 cfr 177 1350 a 1 ethylene vinyl acetate copolymers subject to the limitations and requirements therein. Ethylene vinyl acetate or eva is a copolymer of ethylene and vinyl acetate with a structure as shown below. Ethylene vinyl acetate known as eva is the copolymer of ethylene and vinyl acetate.

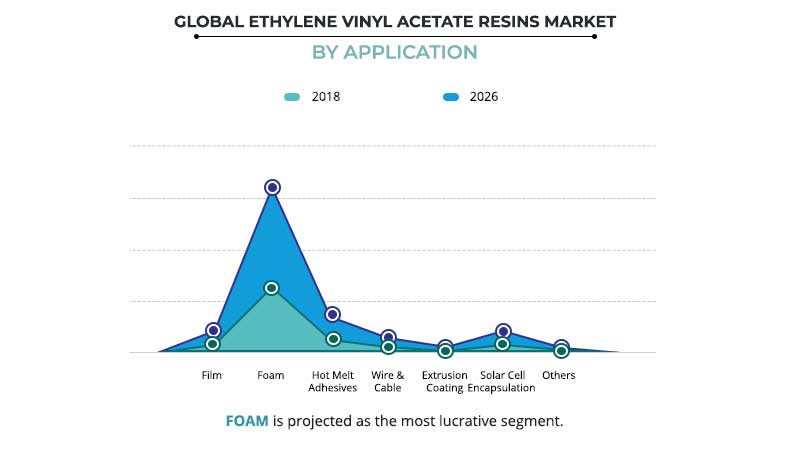

5 13 it is a polymer that approaches elastomeric materials in softness and flexibility yet can be processed like other thermoplastics. As the va content increases crystallinity decreases until at 50 the eva is. 1 201 767 0743. There are three different types of eva copolymer which differ in the vinyl acetate va content and the way the materials are used.

Ethylene vinyl acetate eva also known as poly ethylene vinyl acetate peva is the copolymer of ethylene and vinyl acetate the weight percent of vinyl acetate usually varies from 10 to 40 with the remainder being ethylene.