Fastening Thin Sheet Metal To Thin Pcb

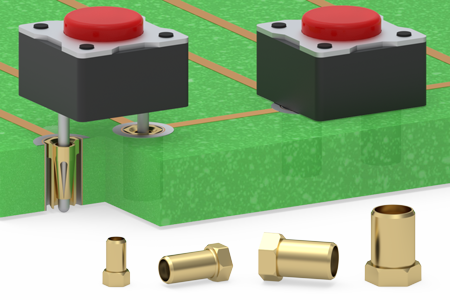

They install in pcbs as thin as 0 40 in.

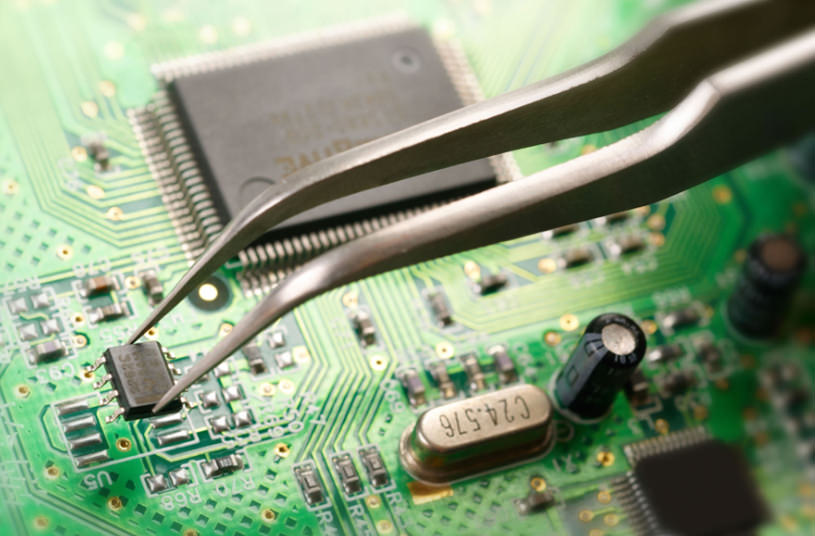

Fastening thin sheet metal to thin pcb. And sheet metal screws or loose. Adhesives for example have been known to fail especially when heat or vibration are present. Joins two sheets of metal or metal to pcb plastic. The economic advantages are obvious but technical implementation often presents a major challenge.

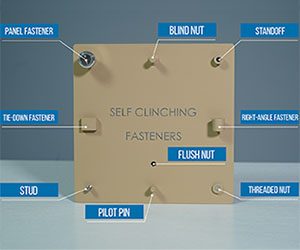

Or component to board. Read more about self clinching technology. Even when the material of both components is the same some problems can be observed for thin sheet metal applications in terms of insufficient mechanical strength and. Panel fasteners come in.

Fasteners for pcb based on our technical expertise in the communication and electronics industry we offer a range of fixations for printed circuit boards which can also be used as threaded fasteners in light alloys such as aluminum. Fastenright supply a large range of sheet metal fasteners which include rivet nuts studs weld studs and threaded fasteners. To enable the fastening of thin sheet materials and thin walled components without the need for internally threaded elements we have developed quick flow self tapping fasteners. Thin sheet metal is a popular choice for use in packaging because it is lightweight and takes up less space.

Custom designs since there are a great many types of standard self clinching fasteners available it is usually possible to choose one to meet your design requirement. Sheet metal usually refers to a thin metal plate with a thickness of 6 mm or less. For sheet metal parts the thickness is the same everywhere. Board materials and other ductile or non ductile thin material.

Specially formed axial grooves around the shank of the fastener cut or broach into the material for a firm fit that resists rotation. However finding a suitable fastening approach has not been easy. Welding can be dirty and time consuming. Integrating a printed circuit board pcb into an assembly is often a custom job.

The fastener installs smooth with the top sheet and flush or sub flush with the bottom sheet. Sheet metal fabrication is a cold processing process which is commonly used for punching bending drawing and forming. Nuts for sheet metal. Usually available from stock.

Lightweight construction methods are advancing all the time. They are simple to assemble and feature high strength and high vibration resistance. If you have a specific problem related to the field of fastening technology with its rich fund of expertise and comprehensive product range kerbkonus has the solution for you.