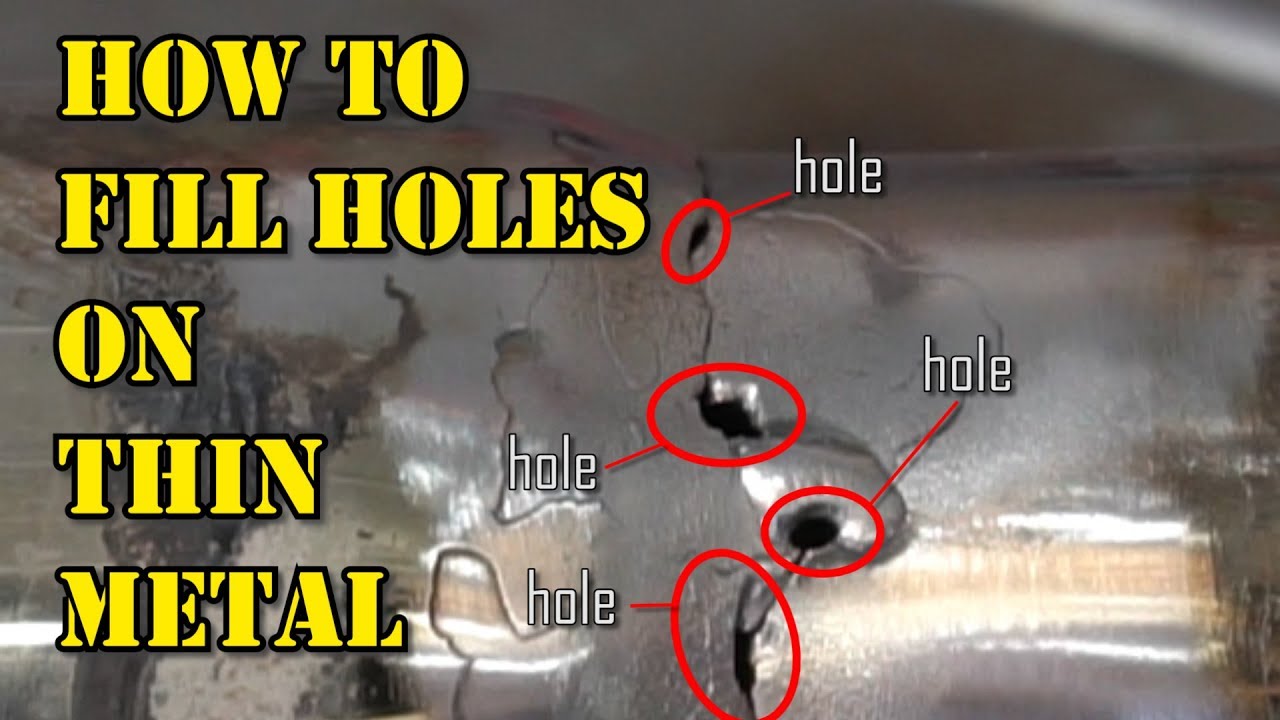

Fill Sheet Metal Holes

In this video matt goes over how to fill holes in a fender using a mig welder and a tig welder.

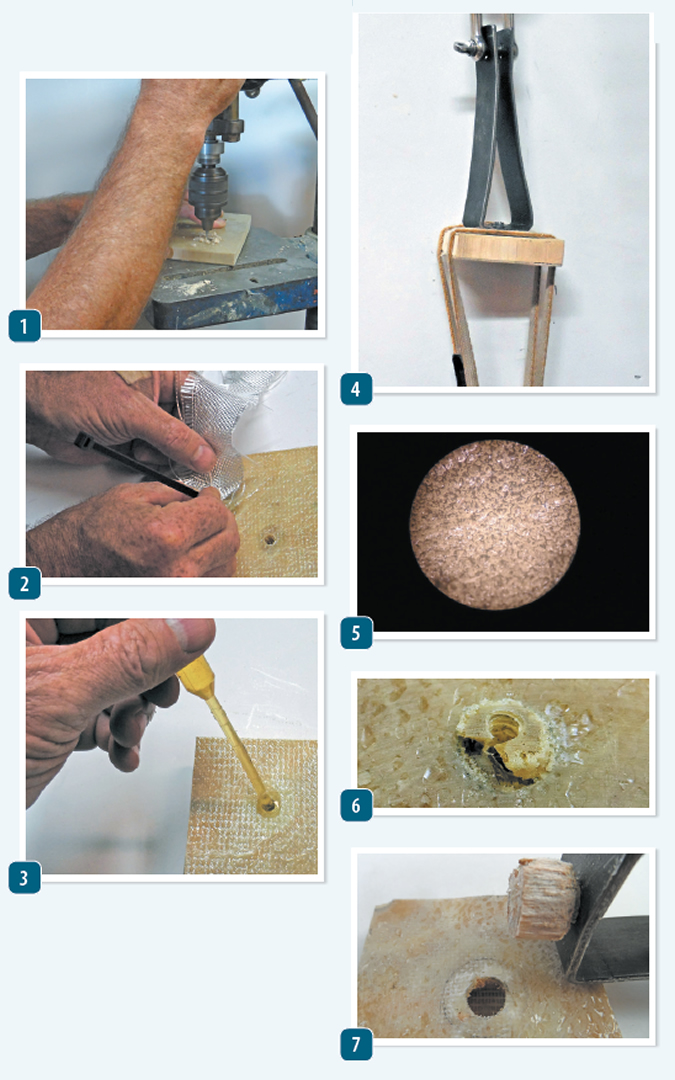

Fill sheet metal holes. The wooden bread layers of the sandwich keep the sheet metal flat and prevent the drill bit from wandering as it bores through the sheet metal. For clean precise holes in thin sheet metal make a wood sandwich. Then build up the epoxy above the surface of the metal and let it slightly overlap the edges of the hole. If the hole needs to contain a liquid a rubber washer can go on the sheet metal screw to render it water tight.

Patching a hole with body filler. Apply epoxy until the hole is filled. Filling the hole working from the front side and using the kit applicator a putty knife or even a stiff piece of cardboard cover the screening with epoxy. Put on goggles gloves and a dust mask for protection.

If you want to delete or remove trim emblems or the like you need to properly metalwork the holes. Select a patch matching the type of metal you re repairing. Small magnets are especially handy in sheet metal rust repair such as holding a small piece of metal inside a hole. How to fill holes and big gaps with your mig welder is a video about welding big gaps and holes on decorative metalwork by mitchell dillman http mitchelldi.

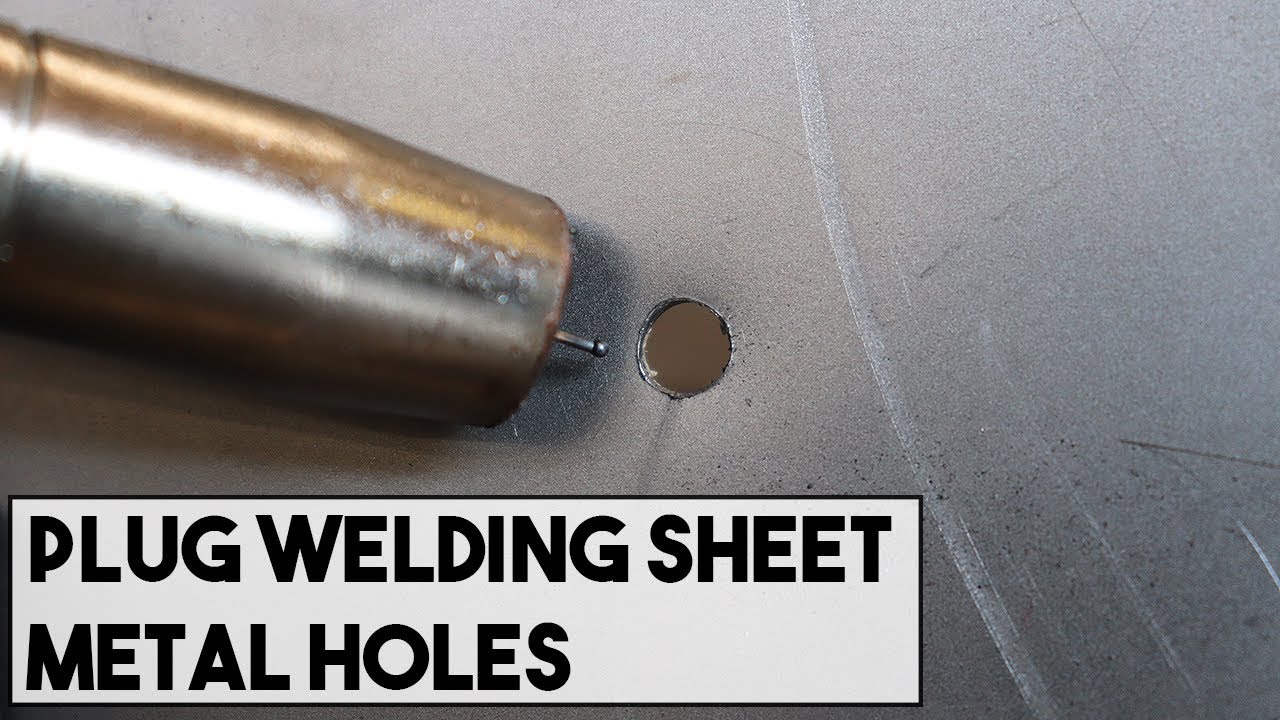

Get a tig 200. Using lineman s pliers the plug is cut to shape slowly snipping into a circle. The job of filling small holes in sheetmetal is deceptively simple. Protect yourself against the.

The kind of plug to use depends on how the thin metal is being used. Perhaps a simple rivet or sheet metal screw can be secured in the hole. Weld thru coating many welding operation leave a section of the weld hidden. Simply sandwich the sheet metal between two pieces of wood and clamp everything down on a table or workbench.

For thicker sheet metal an old copper penny might be a quick source of material. Holes larger than 1 4 need to be filled with metal. A small magnet will help keep the filler metal in place while you weld.