Fitting Flashing To Metal Siding

First step flashing must be installed before the siding so that the siding can cover the top of the flashing.

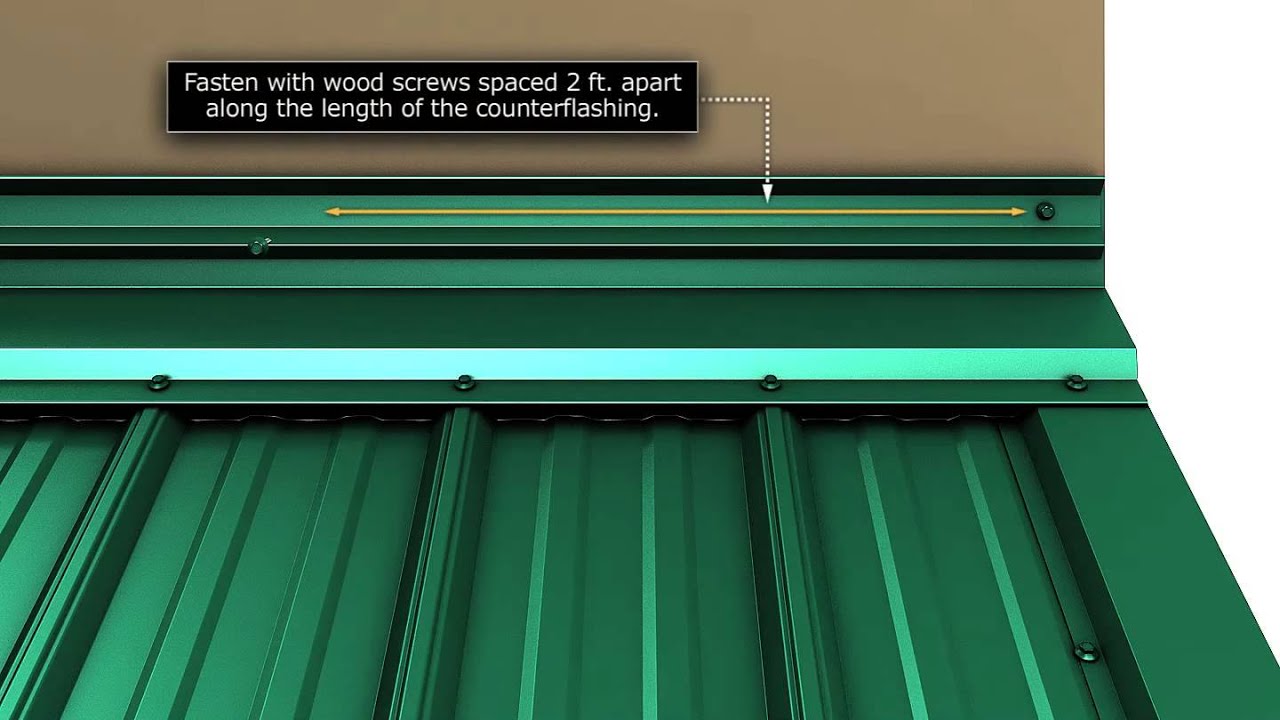

Fitting flashing to metal siding. Depending on the reveal of your siding the flashing length will be inch less than the reveal. There are many different metal flashing shapes but in your case the metal laps over the fascia board perhaps 1 4 inch then is bent at a 90 degree angle to pass over the top of the fascia board then bent again at a 90 degree angle to go up the wall so that it extends behind the first row of vinyl siding. Cut a piece of 2 by 2 inch metal flashing the width of the opening with sheet metal cutters. Have you wondered how to install steel siding on a pole barn.

In the past when customers purchased roofing and siding from us they manufactured flashings themselves or outsourced them to third parties. Install the trim just under the drip cap. Next comes another layer of building wrap installed like the first layer. Apply a bead of caulk to the felt and set the window in the caulk.

On a wall to be covered with wood cement board vinyl or metal. In this video i show how easy it can be. The sheets cover 3 foot so it goes up pretty fast. Corrugated metals incorporated proudly introduces metal flashings as the latest addition to its product line for metal roofing and siding.

Flashing is a strip of metal usually aluminum about 8 inches long and bent at 90 degrees with each side at least 5 inches wide. Second step flashing needs to extend 8 to 14 inches above the shingles according to the national roofing contractors association nrca. Slide one of the 2 inch wide edges under the siding at the top of the window with the opposite edge. Dog ears will be cut on both sides approximately inch from the bottom and then folded to create a stop that will locate itself on the top of the underlying row of siding but not be so long that it will run into the nails that hold the siding of the row being flashed.