Frangible Tank Roof Design

Api 650 gives rules for the design of frangible roof joints in fluid storage tanks.

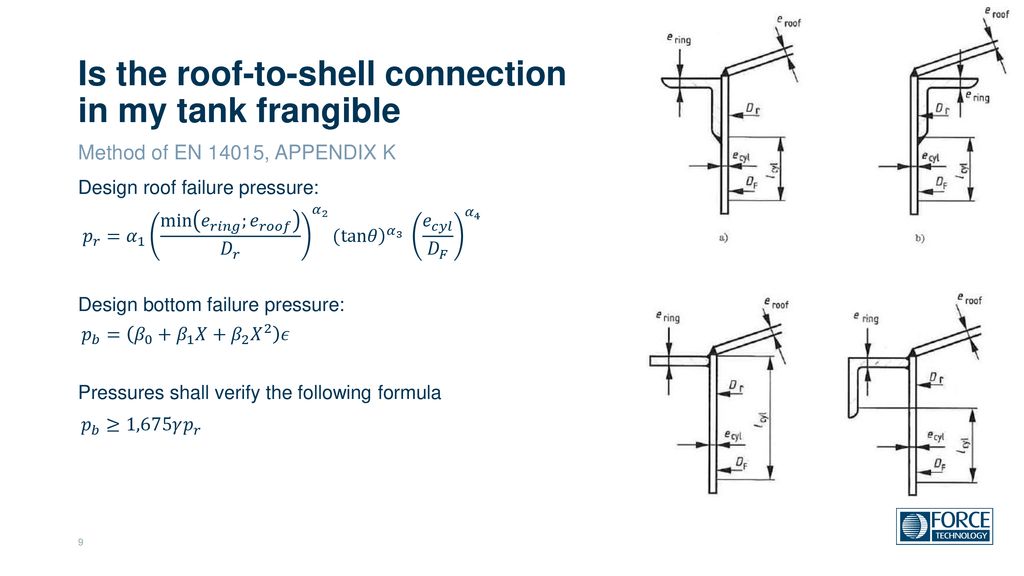

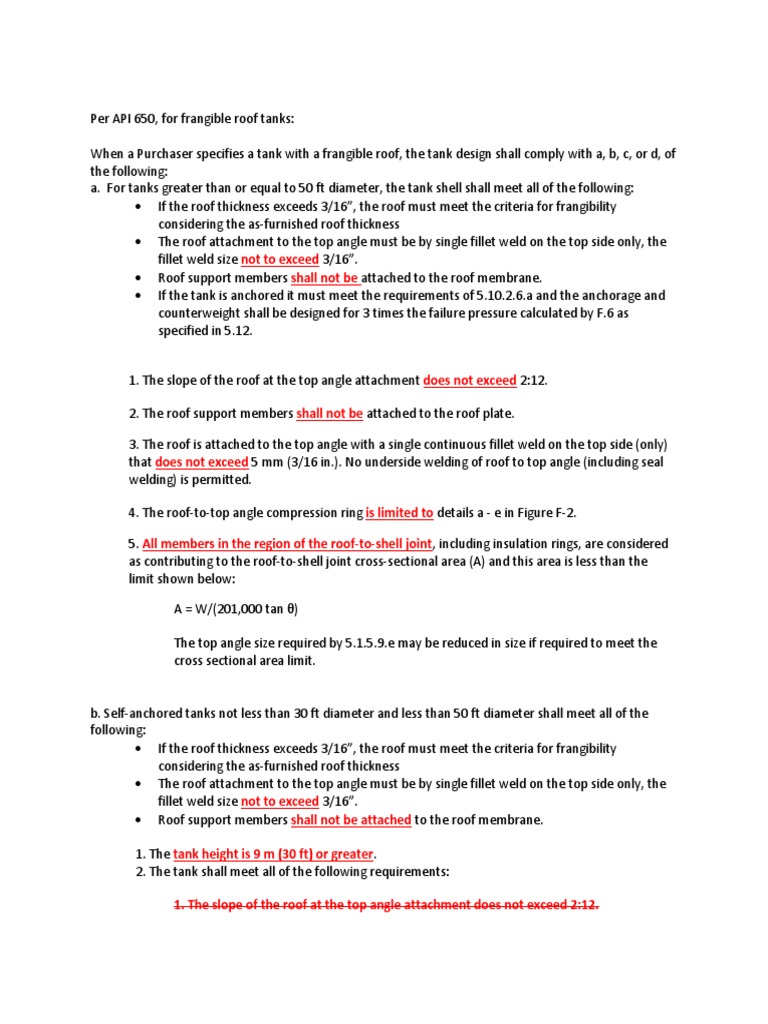

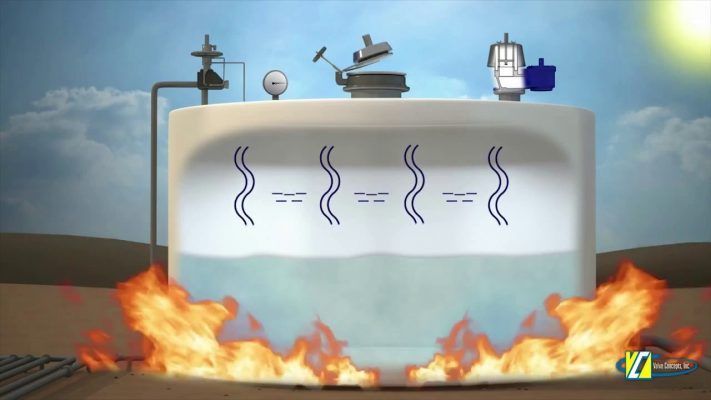

Frangible tank roof design. In fact the frangible roof design fulfills the venting requirements due to deflagrations inside tanks for most tank sizes greater than about 35 feet in diameter. In the event of over pressurization the frangible roof to shell joint is designed to fail before the tank shell or the shell to bottom joint. That is of course if the tanks are built according to the rules for frangible roofs. Failure of the roof to shell junction can be expected to occur when the stress in the compression ring area reaches the yield point says f 6 calculated failure pressure.

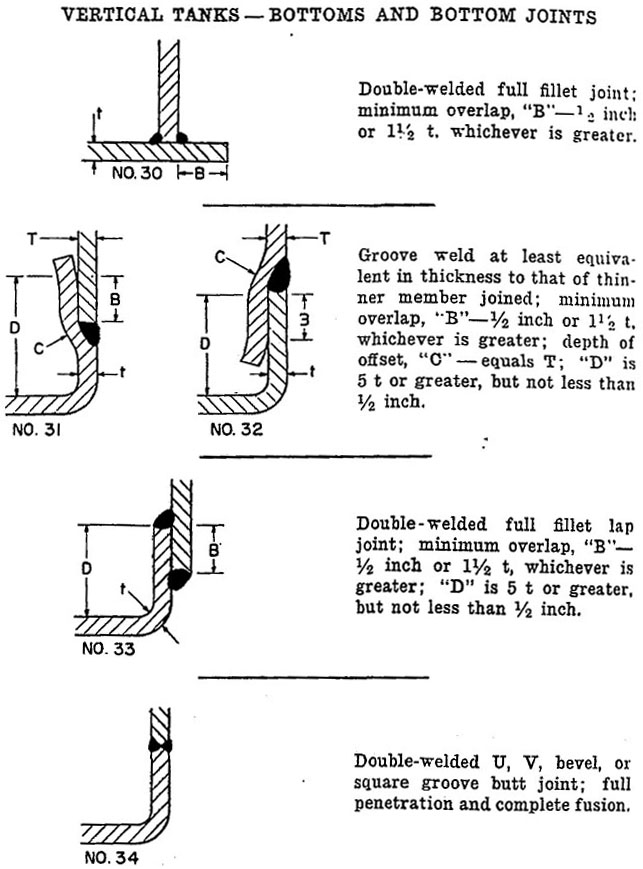

F 4 1 establishes the maximum design pressure p for a tank that has been constructed or that has had its design details established. The reasoning behind present api design formulas is reviewed. This failure is intended to vent the tank and contain any remaining fluid. In such tanks the roof to shell joint is intended to fail in the event of overpressurization venting the tank and containing any remaining fluid.

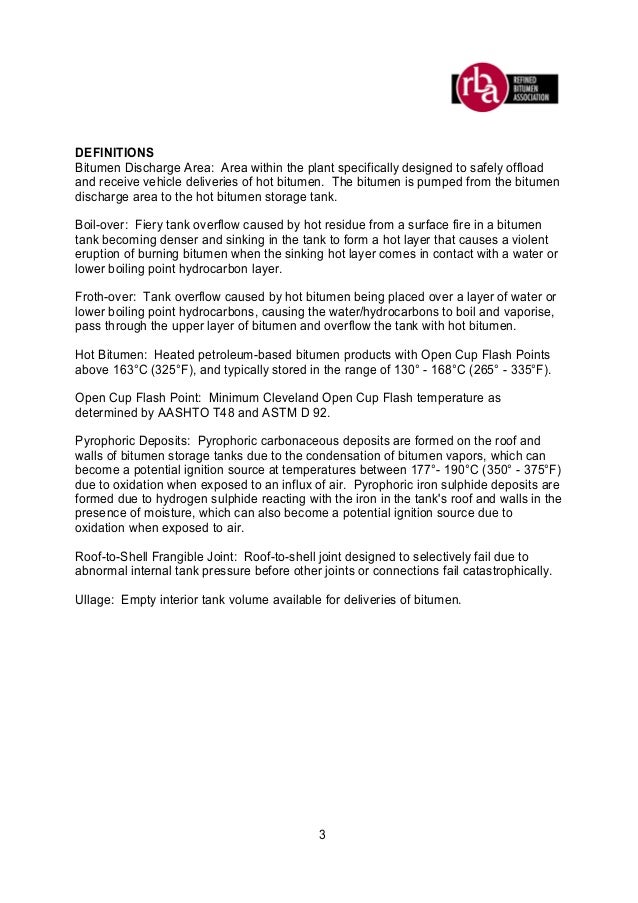

A frangible roof is a roof to shell joint or junction that is weaker than the rest of the tank and will preferentially fail if the tank is over pressurised. The concept of frangible roof only applies to flat bottom cone roof tanks with limited roof apex angle. This video documents the research and testing on frangible joint storage tanks performed at kansas state university and thunderhead engineering. See figures 7 and 8.

The api 650.