Fiberglass Sheet Making Process

Just before all the material is.

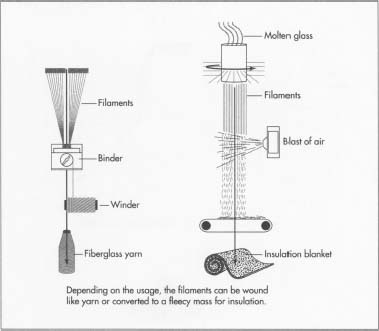

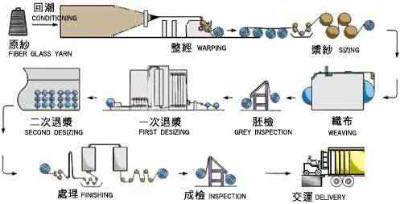

Fiberglass sheet making process. The process typically starts by pulling in two forms of fiberglass reinforcement. I used this method to modify existing bodywork on a friend s. A mold is required to make a fiberglass panel. As the molten glass flows through the bushings jets of air rapidly cool the filaments.

Extra strength can be built into parts by means of sandwich core construction. The fiberglass reinforcements are pulled through a bath of thermoset resin typically polyester or. Fiberglass mat will require about twice as much resin as woven fiberglass for proper saturation. The lower weight fabrics are great for waterproofing.

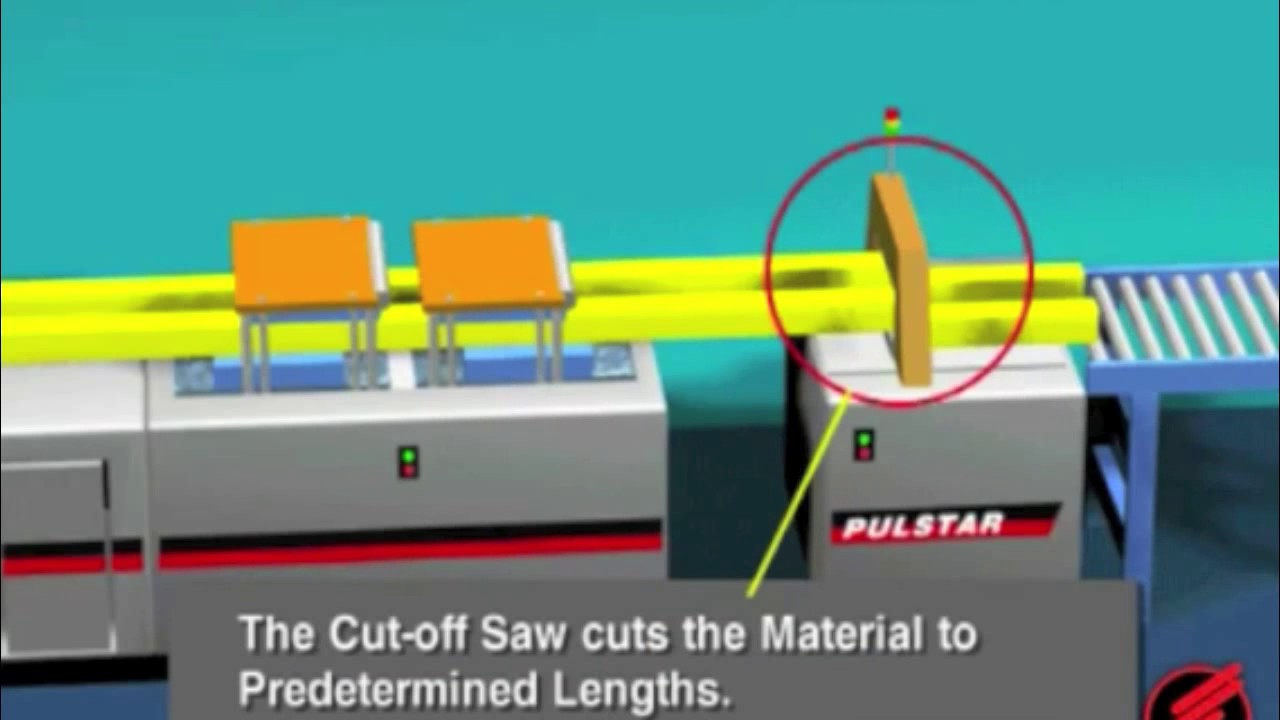

Place two saw horses 6 feet apart. Method 1 creating a mold and pulling a positve. How to make fiberglass sheet with its different steps use in manufacturing and its making for other detail and any other problem to understand the procedure. Please use proper safety equipment when working with resins and fibers.

Carbon fibers are extremely. Lay two 2 by 4s 8 feet long on top of the sawhorses to create an 8 foot work space. Fiberglass cloth also known as fiberglass fabric is low in weight and becomes strong when combined with resin. These filaments fall through a spray of lubricant onto a revolving drum where they form a thin web.

Woven fiberglass matting is stronger than the pressed fibers. Add the hardener according to package instructions. Simple methods for molding fiberglass and carbon fiber step 1. The turbulent bursts of air also break the filaments into lengths of 8 15 inches 20 38 cm.

It becomes transparent when resin is added. Measure an appropriate amount of resin in a metal container. This process involves utilizing a core material such as end grain balsa wood polyurethane foam vinyl foam or honeycomb between two laminate skins. It works well for building composite parts making molds and for fiberglass repairs.

How frp is made 1 reinforcement. Some core materials come in a variety of thicknesses depending on the needs of a particular application. In a kit you will have a pre measured can or bucket of resin.